|

|

| ノリタケの森 Noritake Garden [Photos taken on Oct.13, 2002] |

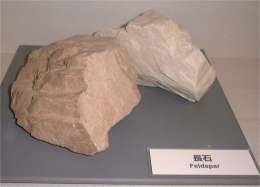

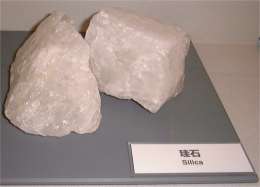

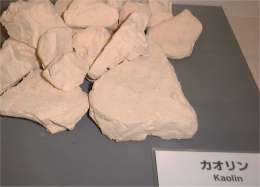

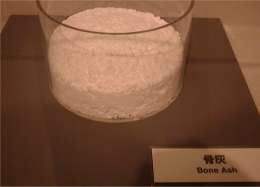

| 名古屋駅近くに築かれたノリタケスクエアは自然な感じで駐車スペースも 広くオアシスと言っても言い過ぎではないでしょう。 学習/飲食/買物/展示の4つのゾーンに分類できます。この中で2箇所 を気に入りました。 1つは敷地内を東西に流れる”せせらぎ”に敷いてある小石。この小石は 使用済み研削砥石の再利用により生まれた浄化材(粒)で、砥石の多孔性 を活用し表面に光触媒(TiO2)をコーティングする事により、太陽光等に よって水質を浄化し、透明度などを高めるというもの。(写真参照) [㈱ノリタケリサイクルセンターと愛知県瀬戸窯業センターの共同出願発明] **<”せせらぎ”に沿った立て看板から引用>** もう1つはクラフトセンター(ここは唯一の有料館;500円/大人)内に展示の ボーンチャイナの製造についての次のような工程の案内です。 ①生地の材料(写真参照)、②原型製作、③ロクロ成形、④流し込み成形、 ⑤組立、⑥仕上げ、⑦締め焼き(写真参照)、⑧施釉、⑨釉焼(写真参照)、 ⑩パターンデザインと転写紙作成、⑪吹き絵付、⑫サンドブラスト、 ⑬転写貼りと金仕上げ、⑭素描、⑮絵付焼成、⑯品質検査、 実演とビデオの両方で内容を確認できるし、解らなければ、実演担当者に 説明を求める事も出来るので、陶磁器の製造工程が解りやすい。 Noritake square built near Nagoya station is natural touch, and the parking space is wide. You will be able to say it is like an oasis. It can be classified into four zones of study / eating and drinking / shopping / exhibition. I was especially pleased in two places in this. One is a pebble with which the "little stream" which flows from east and west is covered in the inside of the site. This pebble is the purification material (grain) produced by reuse of used grinding stone. The porosity of grinding stone is utilized and coating of the photocatalyst (TiO2) has been carried out to the surface. The purification material on which coating was carried out purifies water quality, and raises transparency etc. through sunlight etc. (Please see photo below.) [Patent being applied jointly between Noritake Recycle Center Ltd. and Aichi Prefecture Seto Ceramic Center] ** Most of the above explanation is quoted from the signboard.** Another is guidance of the following processes about manufacture of the bone china of exhibited in a craft center (Only this center is charged : 500 yen / adult). ①Materials for biscuit(Please see photos.), ②Modeling (a model for product is made.), ③Jiggering (The product is shaped from clay.), ④Slip Casting (This process uses a plaster mold to produce complex shape) ⑤Assembling (Delicate and laborious work of putting together pieces that have complex shape.), ⑥Finishing (The work of trimming the edges and smoothing the surface.), ⑦Biscuit Firing (The first firing needed to create bone china.) (Please see photo), ⑧Glazing (Glaze is applied to the surface to give the body a glass-like coating.), ⑨Glost Firing (Firing of glazed product)(Please see photo.), ⑩Creation of Pattern Design and Decal (The pattern to be drawn on the item is delineated.), ⑪Air Brushing (An air brush is used to spray the coloring.), ⑫Sand Blasting (Blasting fine grains to make roughness on the glazed surface.), ⑬Decal Application and Gold Lining (The process of transferring a design printed on a decal and lining the china with gold.), ⑭Hand Painting (Painting is performed using special brushes.), ⑮Decoration Firing (The final firing for completion), ⑯ Quality Inspection (Products are inspected by sight, touch and sound.) You can confirm the contents of the manufacturing process by both demonstration and video. So if you can not understand, you can ask a demonstration person in charge for explanation and the manufacturing process of pottery is intelligible. |

| 長石Feldspar | 珪石Silica | 粘土Clay |

|

|

|

| カオリンKaolin | 骨灰Bone-ash | フィルタープレスケーキ Filter-press-cake |

|

|

|

| 右から締焼き前・後、釉焼後の壷 Jar before and after Biscuit- Firing, Jar after Glost Firing from right hand side |

水質浄化小石(特許出願中) Water-purifying gravel (Patent applied) |

|

|